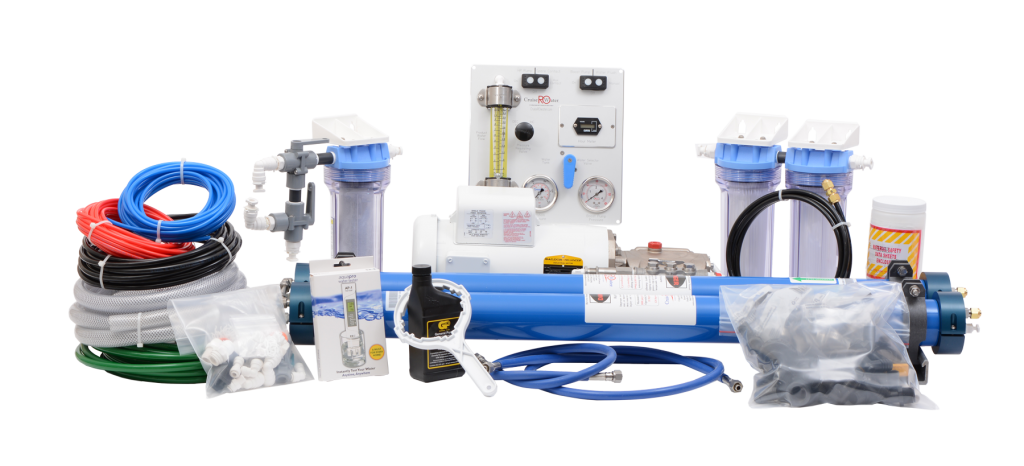

SM60S Simple Complete System

SeaMaker 60 Gallon per hour Water Maker

$7,100 (SM60S) Simple Version with no remote control panel

$7,600 (SM60) AC Version

$7,600 (SM60-50Hz) AC Version

What’s Included:

- High Pressure Pump and Motor Assembly (110VAC, 115VAC, 220VAC, and 230VAC)

- RO Pressure Vessel Assembly

- Pre-filter and Boost Pump Assembly

- Valving and Cleaning Assembly

- Remote Control Panel

- High Pressure Pump and Motor Assembly (12VDC, 220VAC, 115VAC, 48VDC or 24VDC)

- RO Pressure Vessel Assembly

- Pre-filter and Boost Pump Assembly

- Valving and Cleaning Assembly

- Remote Control Panel

Optional Upgrades:

- Remote-Control Panel with TDS Meter (+$200)

- 120VAC Boost pump option available using 1.5Amp (+$200)

- 24VDC Boost pump is available using 6.5Amp (+$200)

- Valving & Cleaning Panel (+$350)

- Automatic Fresh Water Flush ($649)

FEATURES

| Model | Fresh Water Prod. GPH/GPD | High Pressure Pump Amps 120/220V AC | Boost Pump Amps 12VDC | Price |

|---|---|---|---|---|

| SM60 | 53/1272 | 21/10.5 | 5.2 | $7600 |

| SM60-50Hz | 48/1152 | 20.4/10.4 (110-220v) | 5.2 | $7600 |

| Simple Model | Fresh Water Prod. GPH/GPD | High Pressure Pump Amps 120/220V AC | Boost Pump Amps 12VDC | Price |

|---|---|---|---|---|

| SM60S | 53/1272 | 21/10.5 | 5.2 | $7100 |

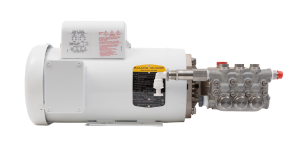

INCLUDED

One General Pump Company triplex plunger pump with a 316 stainless steel manifold and wetted parts, solid ceramic plungers and a nickel-plated crankcase for anti-corrosion mechanically coupled to a 2.5 Hp 120/220VAC 50/60 Hz electric motor. Fitted with a pressure relief valve preset to 1000 PSI. Inlet and outlet fittings supplied and installed on pump.

Three filament wound fiberglass/epoxy pressure vessels

Three filament wound fiberglass/epoxy pressure vessels

Three Dow Filmtec Polyamide thin-film composite high salt rejection RO Membranes Six fiberglass clamps affixed to fiberglass mounting feet, two per pressure vessel

Two 10” clear filter housings with mounting brackets

Two 10” clear filter housings with mounting brackets

One 20-micron pre-filter element

One 5-micron pre-filter element

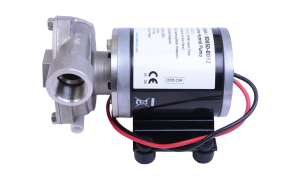

One centrifugal 12V DC Jabsco boost pump (must be installed below the water line)

(Also available in120VAC, 220VAC, and 24VDC)

One clear filter housing with mounting bracket One activated carbon filter element

One 3-way valve for selecting:

- fresh water rinse from ships tanks

- or pickling solution from 5-gallon bucket (customer to provide pickling solution pump)

Remote Control Panel

Remote Control Panel

An anodized aluminum panel with the following system controls:

One hour meter (Standard)

One 0.2 – 2 GPM flow meter

One 0-1500 system pressure gauge

One 0-60 boost pressure gage

One product water selector non-blocking 3-way valve

One stainless steel pressure regulating needle valve One 12VDC boost pump electrical switch

One 120VAC high pressure pump electrical switch One boost Pump pressure gauge

30ft of green 1/2″ Polyethylene sea water tubing

30ft of green 1/2″ Polyethylene sea water tubing

30ft of Black 3/8” Polyethylene brine water tubing

30ft of blue 1/4″ Polyethylene product water tubing 40ft of red 1/4″ Polyethylene brine water tubing

10ft of Orange 3/8″ Polyethylene pickling water tubing

25ft of 3/4” clear braided hose and hose clamps

One cutter for the water tubing

Locking clips for all push connector fittings

Electronic copy of the Installation, Operation and Maintenance manual on a USB Stick (hard copy of manual available on request at our cost of $23)

Two filter housing wrenches for filter element replacement

One container of high-pressure pump oil

2.5 pounds of pickling reagent

One hand-held TDS meter for checking water quality (not included with control panel mount TDS meter)

A baggy of assorted push-to-connect, hose barb fittings, 3/4″ valves and fittings to aid in installation

Replaces standard hour meter with on-panel real-time TDS meter display ($200 adder)

Replaces standard hour meter with on-panel real-time TDS meter display ($200 adder)

One 5ft 3/8″ high pressure braided stainless steel silicon coated hose

One 3ft long 3/8″ high pressure braided stainless steel silicone covered hose for connecting the high-pressure pump outlet to the RO pressure vessel.

Longer or shorter high-pressure hoses available for an additional $10 per foot

DIMENSIONS

The below table provides the length, width, height, and weight of the various water maker modules. The listed dimensions represent the greatest size measurement to create a box that the module can be contained within. However, as can be seen in the module photo images, the modules could actually fit into a smaller space depending upon the installation orientation. These dimensions do not include the room needed for wires or hoses to enter or exit the equipment. All equipment comes with straight fittings. Optional 90-degree fittings are available.

| Module | Length (inches) | Width (inches) | Height (inches) | Weight (pounds) |

|---|---|---|---|---|

| Pump and Motor | 21 | 9.25 | 9 | 73 |

| RO Pressure Vessel | 45 | 14.5 | 6 | 46.5 |

| Prefilter Assembly | 14.75 | 11 | 5.25 | 7 |

| 12V DC Boost Pump | 6.5 | 4.5 | 4.25 | 7 |

| Valving and Cleaning Assembly | 13.75 | 13 | 5 | 3.75 |

| Remote Control Panel (Standard Hour Meter) Depth protruding from back of panel | 2.875 Depth | 11 | 11.25 | 4.5 |

| Optional: Automatic Fresh Water Flush ($649) | 9.75 | 8 | 4 | 3 |

| Optional: Valving & Cleaning Panel ($350) | 5.5 (depth) | 6.25 | 11.25 | 1.5 |

* Please notify us if you plan a 220VAC installation so we can change the standard 120VAC electrical switch for the high-pressure pump motor in your remote panel.

*Please notify us if you plan a 24VDC installation so we can change the standard 12VDC electrical switch for your boost pump in your remote panel.

* Standard Boost pump is a 12VDC self-priming pump.

(Here is a link to a Video we made explaining why we like the 12V DC pump)

* A 120VAC Boost pump option available using 1.5Amp $200 Adder

* A 24VDC Boost pump is available using 6.5Amp $200 Adder

NOT PROVIDED

Watch the video to the right going over the details

Summary of What You Need to Supply

Raw water through hull and shutoff valve

Raw water sea strainer (we recommend one like this)

Electrical installation wire and breakers for the AC and DC Pumps Mounting screws and bolts for the individual system modules

Zip ties and mounting straps for securing the electrical and water lines That’s it! Everything else we provide with the with the water maker.

Questions? We Are Here To Help.

Email or call and talk to the owners of the Company and the Designers, Rich and Charlie, 7 Days-A-Week. If they are awake, they answer!

SALES & TECH SUPPORT

MANUFACTURING & SHIPPING

SKYPE