Boat refrigeration systems must be effective, reliable, and, most importantly, compact. After all, the surface area you have available is quite limited. For this reason, cold plates can be a great option; they have high thermal conductivity and are relatively small.

This blog post will define a cold plate system, explain how it works, and examine its benefits to marine refrigeration systems. So, let’s take a deeper look at the technology that assists cruisers and boaters in keeping their food and beverages fresh while on the sea.

What Are Cold Plates and How Do They Work?

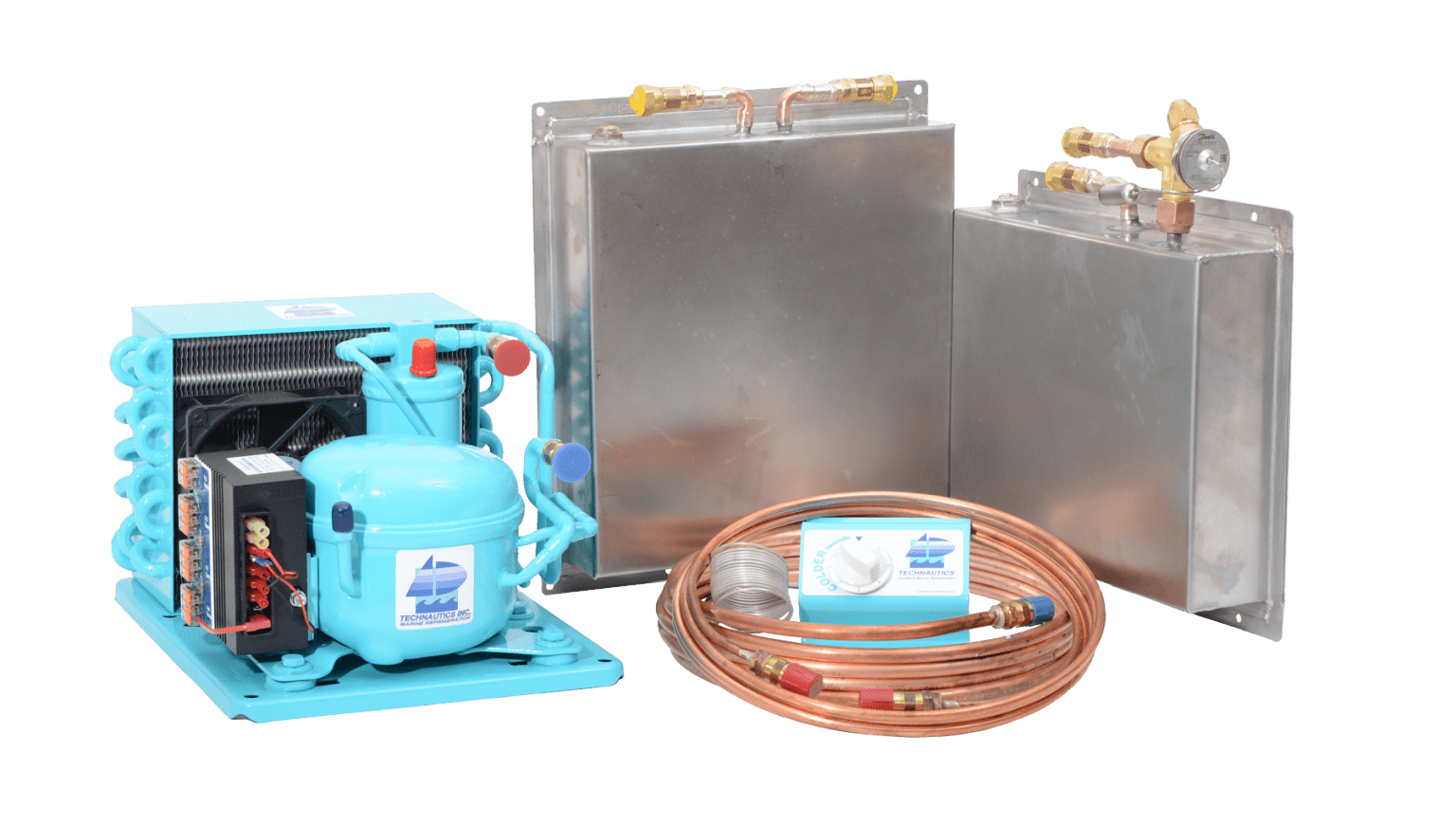

A cold plate is a stainless steel container in a refrigerator or freezer box with coiled tubes inside. While the fridge runs, the refrigerant freezes to a solid state. After the solution freezes, the compressor turns off, and the cold plate works as a huge ice block, gently melting back into a liquid while removing heat from the fridge.

Depending on how big the cold plate is and how hot the box is, it can keep things cool for at least 24 hours. It acts as a temperature battery, storing cold when there is extra power and cooling when there isn’t. A large capacity high amp draw 120V compressor is commonly used to solidify the cold plate in a few hours.

Most cold plates are made of metal and have channels cut into them so a refrigerant can flow through them. Channels can be made into different shapes and sizes. Various channels allow the cold plates to absorb and move large amounts of heat more efficiently. The liquid used, the flow rate, and the material used to manufacture the cold plate all affect the heat transfer rate’s effectiveness.

Importance of Cold Plate Cooling System in Marine Refrigeration

Cold plate systems outperform standard refrigeration systems in a marine setting when space is limited. The plates are substantially smaller than a typical evaporator since they can be put directly into the walls or floor of the refrigeration compartment. As a result, there is more room for storage, and the space is used more effectively.

Operating without a steady power supply is the most important benefit of cold plate systems in a marine setting. By charging the plates during periods of high power availability, the refrigeration system can continue to deliver cooling even after the boat’s generator is turned off. This not only helps by reducing noise and fuel consumption but also gives you an extra safety net in case of an emergency.

Get the Best Cooling System for Your Boat

If you’re looking for a new marine refrigeration system, consider the benefits of the cold plate design. These systems are ideal for any boat owner wishing to increase aboard comfort and storage because of their efficient, dependable, and compact design.

Cold plate systems are essential to marine refrigeration, providing effective and dependable cooling in a small and space-saving design. Whether you want a cold plate cooling system or a standard system, Cruise RO Water and Power offers various reverse osmosis water makers and refrigeration solutions. Contact us today to get the best system for your boat.