CruiseRO, Proud & Trusted Frigomar USA Partner for the Western USA & Mexico

Frigomar USA’s success has been built upon almost fifty years of innovation, state-of-the-art technologies, and a guarantee of assistance. All Frigomar products are designed, produced, and assembled in Italy and cover the key sectors within the nautical environment. At Cruise RO, we are authorized distributors for Frigomar systems, including:

FRIGOMAR AIR CONDITIONING SYSTEMS

Centralized

- Three Phase Chiller Unit Inverter

- Single Phase Chiller Unit Inverter

- ON/OFF Chiller

- Fan Coils

- Air Handling Unit

- Air Extraction Unit

Self-Contained

- Self Contained Unit Inverter AC

- Self Contained Unit Inverter DC

Accessories

- Switchboards

- Thermostats

- Air Conditioning Accessories

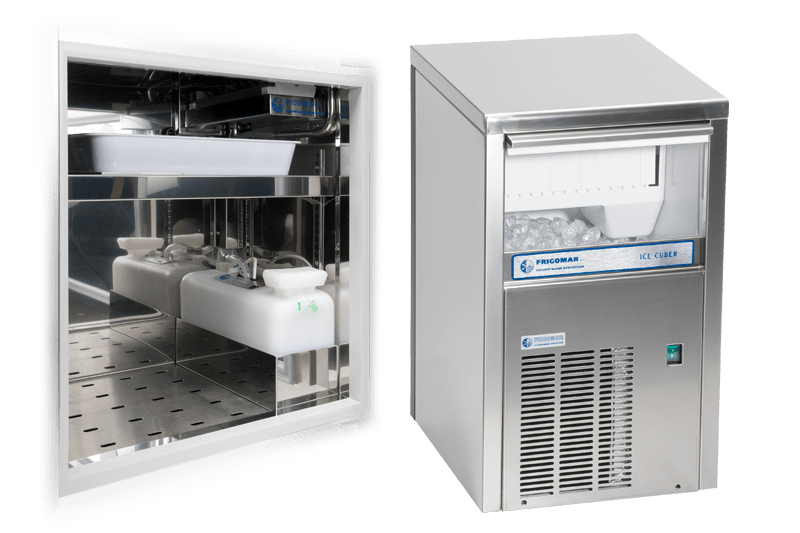

BOAT REFRIGERATION SYSTEMS

Centralized

- Custom-Made Refrigerators

- Standard Centralised Refrigerators

- Cold Rooms

- Wine Coolers

- Compressors

Self-Contained

- Custom-Made Refrigerators

- Standard Independent Refrigerators

Accessories

- Electric Switchboards

- Refrigeration Components

- Replacement Parts

ICE MAKING SYSTEMS

Ice Makers

- Ice Maker

- Ice Maker Kits

- Air Condensed Ice Makers

- Water Condensed Ice Makers

Accessories

- Replacement Parts

High-Quality Refrigeration Solutions for Boat Owners

FrigomarUSA has always believed in and invested in developing and optimizing the exclusive BLDC Inverter technology. They have succeeded in producing units that are more and more advanced and that offer increasingly greater performance. The size and weight have been further reduced by optimizing the heat exchange surfaces and through the meticulous choice of materials. If a further reduction in the weight is required, please contact our technical office to discuss possible custom-made solutions.

Boat AC Systems

The new generation of Frigomar air conditioning systems features the BLDC Inverter technology. This boat AC system technology offers the following benefits:

- Every marine air conditioning system design is compact and low-weight.

- Greater energy efficiency.

- Modularity and simplicity of installation.

- Special materials that ensure greater corrosion resistance.

- Thermostats with touch screen.

- Communication via WI-FI and a dedicated APP.

Boat Refrigeration Systems

Frigomar also offers a range of standard and custom marine refrigeration systems for mega yachts and small boats. Their design and custom-made refrigeration options offer a range of benefits, including:

- Stainless steel (AISI 316) construction.

- Shape and dimension are completely customizable.

- Variety of exterior layouts.

- “Customizable” stainless steel interior layout.

- Flush or hinged doors.

- Concealed hinges and handles.

- Full extraction drawers.

Ice Making Systems

Frigomar also offers ice machines of all capacities to meet your ice production needs while on board. Their ice makers include the following advantages:

- Wide range of options to choose the type of ice and quantity you need.

- Choose between classic ice cubes, ice fingers, and ice flakes.

- Production capacities from 18 to 60 kg produced in 24 hours

- Storage capacity from 4 to 9 kg.

Find the Right System for Your Boat

Looking for a new ice maker, refrigeration, or marine air conditioner for your boat? No matter the size of your boat, CruiseRO can help you find the right system for your needs. From the smallest and most lightweight systems to the largest and most powerful, we have the perfect product for you.

We are a certified Frigomar USA partner for the Western US and Mexico and can help you enhance your boat with the most efficient and innovative equipment. Contact us today to find the perfect system for you.

Why Choose CruiseRO Water & Power?

Experience

At Cruise RO Water and Power, we have experience as cruisers and industrial manufacturers. We take our knowledge and expertise and craft top-notch systems that meet your onboard needs.

Quality

We are committed to offering high-quality products that offer strength and durability. Our product selection meets your power, durability, and quality needs, ensuring your investment is a long-lasting solution.

Affordability

We believe water on board is not a luxury but a necessity. We craft cost-effective systems with non-proprietary parts, which minimizes upfront and replacement expenses.

Adaptability

Our company also offers custom watermakers perfectly tailored to your budget, production, and size needs. Our water supply solutions adapt to your sailing adventures with ease.

Hear from Our Satisfied Clients

Questions? We Are Here To Help.

Email or call and talk to the owners of the Company and the Designers, Rich and Charlie, 7 Days-A-Week. If they are awake, they answer!

SALES & TECH SUPPORT

MANUFACTURING & SHIPPING

SKYPE

FAQs

Boat AC units work with a series of components that together provide cool and comfortable air on board:

- The compressor serves as the engine, pressurizing the refrigerant gas to raise its temperature significantly.

- The condenser then releases heat, turning the gas into a high-pressure liquid.

- The expansion valve controls the flow of the liquid, reducing its pressure and temperature.

- In the evaporator, the refrigerant absorbs heat from the surrounding air, creating cold air for the cabin.

- A blower fan ensures proper air circulation, while a return air grille and filter clean and enhance air quality.

Follow these steps to winterize your boat AC unit:

- Remove any debris, dust, or dirt from the unit.

- Disconnect the AC unit from any power sources.

- Drain any water from the air conditioner and its water lines.

- Check the refrigerant levels. If they are low, recharge the unit to the manufacturer’s recommended levels.

- Contact a qualified marine mechanic in order to recharge the AC unit.

- Inspect the AC unit’s wiring and insulation for signs of wear, damage, or rodent infestation

- Finally, cover the air conditioner with a sturdy, weatherproof covering.

Here are some tips for troubleshooting your boat’s AC system:

- Clean the vents and filters.

- Check the AC pump for any leaks or odd noises.

- Check the blower for any damage or blockages and the ducts for leaks or disconnections.

- Look for any fault or warning messages on the display panel.

- Check the AC system is powered and that all connections are safe.

- Check for a clogged drain and remove any blockages.

- Check refrigerant levels and contact a professional if you suspect a leak.

- Look for ice accumulation or debris in the evaporator coil, and clean it if necessary.

- To install your marine refrigeration system, you need to gather the tools and materials. These include the marine AC system, wiring, a circuit breaker, mounting brackets, and insulation materials.

- Select a suitable location for the AC unit. Prioritize ventilation and easy maintenance access.

- Securely attach the AC unit to the chosen location using the mounting brackets.

- Carefully install the ducting to ensure optimal airflow throughout the boat’s interior.

- Follow the manufacturer’s guidelines to connect the AC unit to the boat’s electrical system.

The cost of an AC unit can vary widely. Brand-new, basic units for smaller boats can be as low as $1,200, while larger, more advanced units with enhanced features may cost $2,000 or more. Installation costs, typically ranging from $3,000 to $4,000, should also be considered for a complete estimate. Professional installation is vital for ensuring long-term efficiency.

To determine the appropriate size of your boat AC unit, follow these steps:

- Determine the total cubic footage of the area you intend to cool.

- Evaluate the insulation and sun exposure of the area, as well-insulated spaces will require less cooling capacity.

- Account for heat-producing equipment like ovens or machinery and add their heat load to the cooling requirement.

- Consider the number of occupants projected for the boat and select an air conditioner with higher capacity for frequently occupied spaces.