CoolBlue Cold Plate Cooling Systems

As cruisers, we understand the need for efficient cooling systems while on board. Whether you own a cruiser, a yacht, or any other type of vessel, high-power refrigeration systems are a must. CoolBlue Cold Plate Refrigeration Systems are cutting-edge, designed to keep your boat’s provisions fresh and chilled on every voyage.

We engineer our cold plate cooling systems to provide exceptional cooling performance even in the harshest marine environments, keeping your perishables fresh and your beverages ice-cold. Explore our page to discover the perfect marine cold plate system for your vessel and enjoy a hassle-free sailing experience.

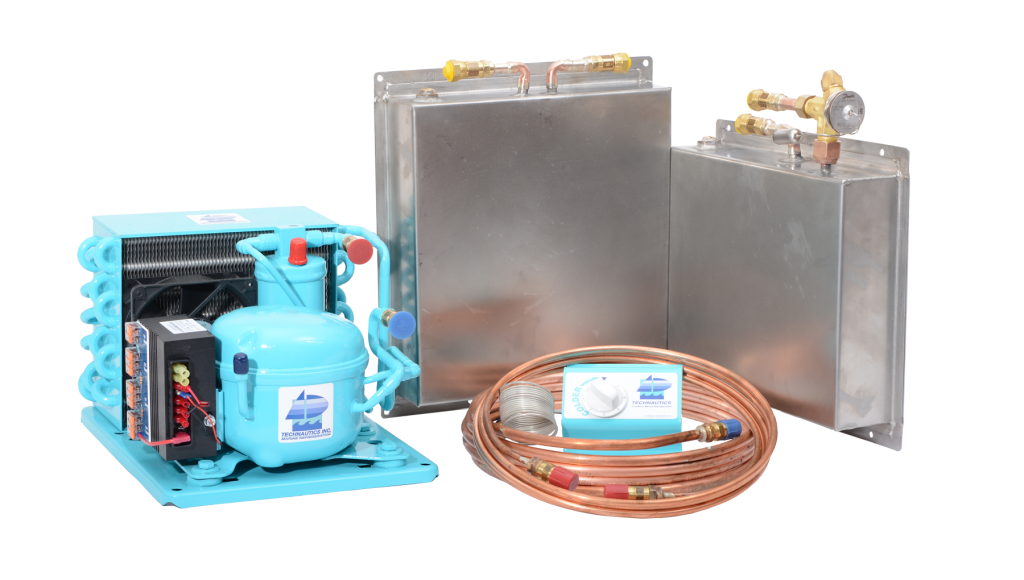

CoolBlue Marine Cold Plate System

Discover the ColdBlue cold plate cooling systems. We design our products with an array of impressive features, ensuring superior thermal performance and reliability. Crafted to enhance your boating experience and help you meet your refrigeration needs, the ColdBlue Cold Plate Refrigeration Systems feature:

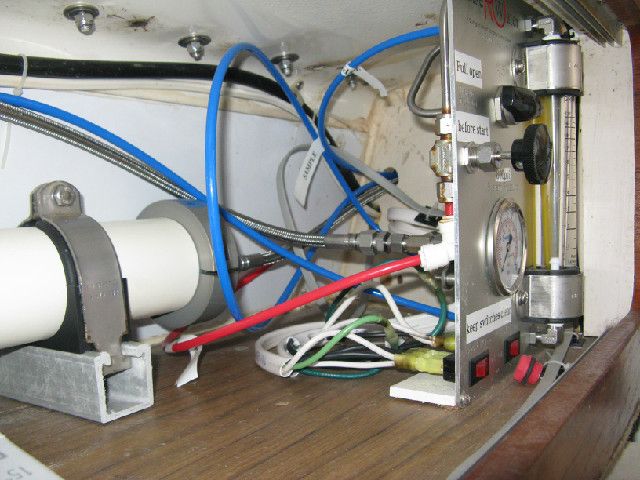

- Fin/Tube holding plate with preset expansion valve custom configured to fit your box

- Holding plate mounting brackets

- DC condensing compressor unit operating on 12v or 24v

- 12ft copper tube sets with Aeroquip self-sealing connector ends (custom sizes available upon request)

- Thermostat with mounting bracket

- The ONLY 5-Year Warranty in the Marine Refrigeration Business with 7 Day a week Customer Service

- LED Digital remote Temp display

$3,150

Marine Refrigeration Excellence

COOLBLUE cold plate cooling systems are as reliable as your land-based 120v kitchen refrigerator while using half the daily amps of other 12v refrigeration systems. Utilizing the latest technology in variable speed compressor design, low amp 12v fan, an oversized condensing coil, and holding plate with preset expansion valve.

The COOLBLUE cold plate cooling system operates simply and efficiently, eliminating the complexity and excess power associated with water-cooled systems. While other 12v systems require water cooling at temperatures above 90F, COOLBLUE operates at ambient temperatures up to 120F without losing system efficiency or thermal management.

All Technautics modular refrigeration systems are built, pre-charged with 134a refrigerant, and pre-tested prior to shipping. The systems are also cruiser installable and serviceable without any special tools, gauges, or refrigeration experience.

CoolBlue Advantages

For cruisers looking for cost-effective and efficient refrigeration for their boat, the high-performing CoolBlue marine cold plate system stands out. It offers a range of advantages, including:

- 45 YEARS of Marine Refrigeration Experience SINCE 1968!

- COOLBLUE uses 1/2 the power as other 12v Systems

- 24AH/Day for a 7 cubic foot fridge/freezer with R-30

- Offers the only 5-year warranty due to the robust design

- No refrigeration technician or experience needed

- Stainless steel holding plate resists corrosion and leaks

- No water cooling needed even at ambient temps of 120F

- COOLBLUE systems are pre-charged, pre-tested and built in Escondido, California USA.

| CoolBlue | Evaporator Systems | |

|---|---|---|

| WATER COOLING | Not needed, even at 120 ° F (50 ° C) | Required at temperatures over 90 ° F (32 ° C) |

| ALTERNATE AIR | Not needed | Suggested |

| POWER CONSUMPTION in a 7 cubic foot (200 liters), R-30 box | 24 amp hours/day | 48 amp hours/day |

| FREEZER CAPACITY in a 7 cubic foot (200 liters) box | 1/3 freezer, 2/3 refrigerator 120 pounds of frozen food | 12 pounds of frozen food |

| DISTANCE from compressor to box | 2-50 foot customized per order | 9 foot only |

| PLATE | Stainless Steel | Aluminum, thin & easily punctured, susceptible to corrosion |

| SERVICEABILITY | Site glass and service ports provided, serviceable by owner | No service ports provided, only serviceable by refrigeration technician |

User Manual

To download a copy of the CoolBlue manual with technical specifications

along with detailed installation and operation instructions, click the button on the right.

Find the System You Need at CruiseRO

CruiseRO Water & Power is your all-in-one solution for cruising needs. Whether it’s reverse osmosis systems for water production or marine cold plate systems, we have the perfect equipment for any vessel.

As cruisers ourselves, we understand the need for having reliable equipment while on board. At CruiseRO, we offer the highest quality marine equipment to help you enhance your cruising experience. Meet all your onboard needs and save costs with our efficient, energy-saving, and cost-effective marine equipment.

We also offer reliable customer service seven days a week. So, if you need help finding the perfect system for your vessel or placing your order, please don’t hesitate to contact us. We’re glad to help.

Why Choose CruiseRO Water & Power?

Experience

At CruiseRO Water and Power, we bring a unique blend of sailing and manufacturing expertise. We understand your needs and deliver tailored solutions to meet them.

Quality

Our comprehensive range of high-quality products includes cold plate cooling systems and RO systems. Our commitment to durability and quality ensures your satisfaction on every voyage.

Affordability

We offer cost-effective solutions. We build our systems with non-proprietary parts, reducing upfront costs and future replacements, ensuring you get the best value for your investment.

Adaptability

Experience true adaptability with our custom watermaker systems. At CruiseRO Water and Power, we design and manufacture solutions tailored to your precise needs.

Hear from Our Satisfied Customers

Questions? We Are Here To Help.

Email or call and talk to the owners of the Company and the Designers, Rich and Charlie, 7 Days-A-Week. If they are awake, they answer!

SALES & TECH SUPPORT

MANUFACTURING & SHIPPING

SKYPE